Overview:

Mold powder is mainly used in the continuous casting and steelmaking process, evenly sprinkled on the molten steel surface in the mold to lubricate, keep warm, prevent oxidation and absorb non-metallic inclusions. Mold powder is an indispensable auxiliary production material in the production process. In the process of evenly distributing the mold powder to the molten steel surface of the mold, the amount of mold powder should be controlled, and the thickness of the mold powder should be within a certain range. If the coverage thickness of the mold flux is too thin, it will cause no heat preservation, oxidation of molten steel, inclusions, cracks, large drawing resistance, steel leakage, etc. At the same time, the coverage thickness of mold flux should not be too thick, they cant melt in time with too much mold powder, if the molten steel is churning, it is easy to get the mold powder into molten steel at this time, resulting in mold leakage. Therefore, the amount of mold powder must be controlled within a reasonable range. The detection and control of mold flux thickness is very important, especially for the steel plants which are strict with the steelmaking production process.

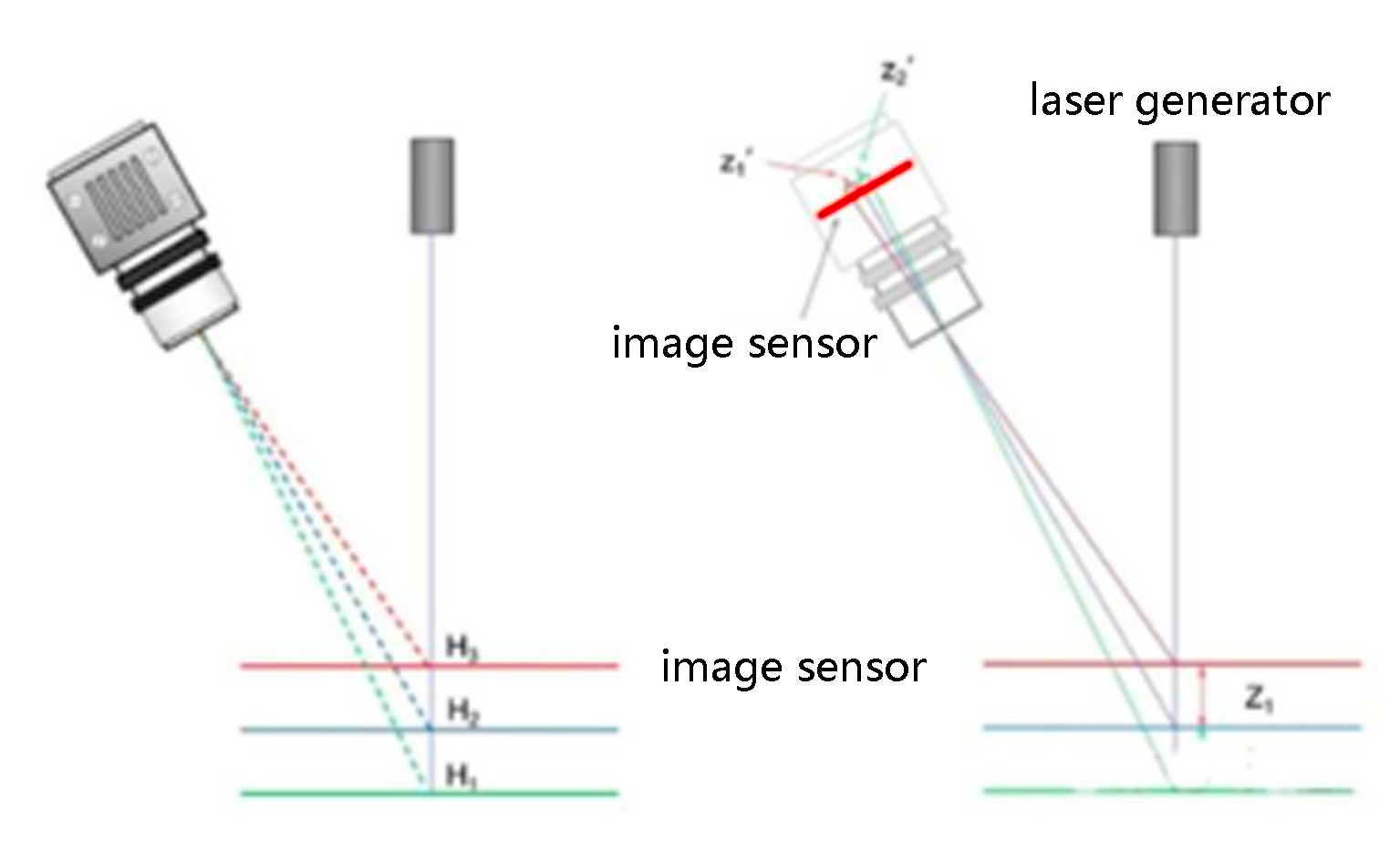

The detection principle:

The mold flux detection system developed by Wuhan CenterRise M&C Engineering CO., Ltd. uses the laser triangular sensor fixedly installed above the mold to obtain the height h1 by scanning the upper surface layer of mold flux with high-precision laser triangulation. When the laser measuring head is placed each time, the height h3 of the upper nozzle of the mold will be marked, and the system through the PLC system which is connected to the continuous casting machine through the network to introduce the height h1 of the mold liquid level. Through the calculation of three heights, we can get the thickness of mold powder(900mm is the depth of mold).

The features:

The equipment is easy to install and use. When we are using, the laser rangefinding sensor can be placed directly above the mold without affecting production.

The system can be interlocked with the automatic mold powder feeding system to automatically adjust the amount of mold powder, so as to automatically control the amount of mold powder within a reasonable range and realize intelligent automatic mold powder feeding.

The parameters:

Measurement range:0-50mm

Temperature measurement range: -20℃-700℃

Equipment installation distance:<750mm

System measurement accuracy:1mm

Laser measurement accuracy: 0.1mm

Frequency: 700-2000Hz

Cooling method: air-cooled purging

Installation method: rail sliding installation, can be slid out during maintenance

Storage period: data can be stored for more than 2 years

Communication method: Industrial Ethernet or Profibus-DP

Wuhan CenterRise M&C Engineering CO., Ltd.

more info, please contact

Mobile: +86 13995588597

Wechat/whatsapp:+86 15727288019

sales@whzfy.com

=Mention Arzooclassifiedads.club when calling seller to get a good deal

Bids